Product Details:

Payment & Shipping Terms:

|

| Material: | Stainless Steel 316 L | Materials Morphology: | Powder |

|---|---|---|---|

| CNC Machining Or Not: | Not | Micro Machining Or Not: | Not |

| Quotation Leadtime: | Within 24 Hours | Business Type: | Manufacturer&factory |

| Tolerance: | +/-0.05mm | Price: | Reasonable And Negotiate |

| Avaliable Files: | Step/stp/igs/x_t/stl | Material Capabilities: | Cobalt-chromium Alloy,stainless Steel 316,titanium |

Auto Gear Metal Laser Sintering 3d Printing And Rapid Prototyping

|

Advantages |

1. Compared with traditional manufacturing techniques, the speed of DMLS is the most

obvious because no special tooling is required and parts can be built in a matter of hours.

2. DMLS allows for more rigorous testing of prototypes. Since DMLS can use most alloys, prototypes can

now be functional hardware made out of the same material as production components.

3. Complex geometries and assemblies with multiple components can be simplified to fewer parts with a

more cost effective assembly. DMLS does not require special tooling like castings, so it is convenient for

short production runs.

4. DMLS is also one of the few additive manufacturing technologies being used in

production. Since the components are built layer by layer, it is possible to design internal features and

passages that could not be cast or otherwise machined.

|

Applications |

· Metal parts, fire test parts, fixture direct manufacturing and model demonstration test.

· Development of new products.

· Creative design and display of culture, creativity, clothing, household goods and other.

· Research and development of implants, teeth, skull repair, prosthetics and medical

equipment.

· Product design, rapid production of high-precision injection molds.

|

Technical Specifications for Direct Metal Laser Sintering |

|

Technique Specifications of EOSINT M 280 |

Equipment |

|

|

Building volume |

250 mm x 250 mm x 325 mm (9.85 x 9.85 x 12.8 in) |

|

| building platform | 9.85 x 9.85 x 12.8 in | |

|

Laser type |

Yb-fibre laser, 200 W oder 400 W (optional) |

|

|

Precision optics |

F-theta-lens, high-speed scanner |

|

|

Scan speed |

up to 7.0 m/s (23 ft./sec) |

|

|

Variable focus diameter |

100 - 500 μm (0.004 - 0.02 in) |

|

|

Power supply |

32 A |

|

|

Power consumption |

maximum 8.5 kW / typical 3.2 kW |

|

|

Nitrogen generator |

integrated |

|

|

Compressed air supply |

7,000 hPa; 20 m3/h (102 psi; 706 ft3/h) |

|

|

Argon supply |

4,000 hPa; 100 l/min (58 psi; 3.5 ft3/min)(optional) |

|

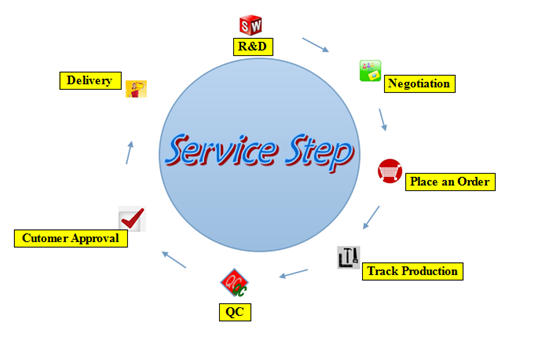

Service Step for a Project